By Dinesh Sinha, BDS, PHD, Senior Technical and Marketing Manager Dental Division, Kuraray America, Inc.

Since the early 2000’s, the global all-ceramic restoration market, including that for zirconia, has been growing rapidly. Increasing market demand resulted in various dental manufacturers marketing different dental zirconia types that can be used in many dental prosthetic applications. Today, dental ceramists play a key role with the latest CAD/CAM technology to provide high performance zirconia prosthetics with more precision and aesthetics for treatment needs.

Zirconia is a polycrystalline ceramic. This means that it is entirely composed of crystals, with no glass phase. The presence of an entirely crystalline microstructure brought strength to zirconia and gave initial formulations an opaque appearance with low translucency. The translucency of zirconia is improved by changing the atomic arrangement within the crystals of zirconia (most commonly known as translucent or aesthetic zirconia). There are several key factors dental ceramists should know when selecting zirconia:

1. Type/brand of zirconia

During the industrial process of making dental zirconia (zirconium dioxide), Yttria (Y2O3) is added to make refined zirconia stable at room temperature. Yttria also contributes to increasing the translucency of zirconia, but also conversely reduces its strength. The most common method of classifying zirconia is by Yttria concentration (i.e., 3Y, 4Y & 5Y). Many dental manufacturers use/buy zirconia from one large industrial ceramic manufacturer. This classification helps to understand and describe the properties of zirconia where the primary powder source is the same. 3Y is the strongest and least translucent, whereas 5Y is the highest translucency and lowest strength.

Fig. 1. Kuraray Noritake Dental Inc. original KATANA™ Zirconia powder.

Most dental zirconia manufacturers purchase raw zirconia powder from a third party. Only a few manufacturers like Kuraray Noritake Dental Inc. use their own proprietary original zirconia powder formulations (Figure 1). The company can thereby more accurately control the chemical and physical make-up, not only with Yttria concentration, but also parameters like grain or particle size, as well as sintering temperature. Kuraray Noritake has KATANA™ as an umbrella brand with three different options of strength and translucency in multi-layered formulations: KATANA™ HTML PLUS, STML and UTML.

2. Strength of dental zirconia

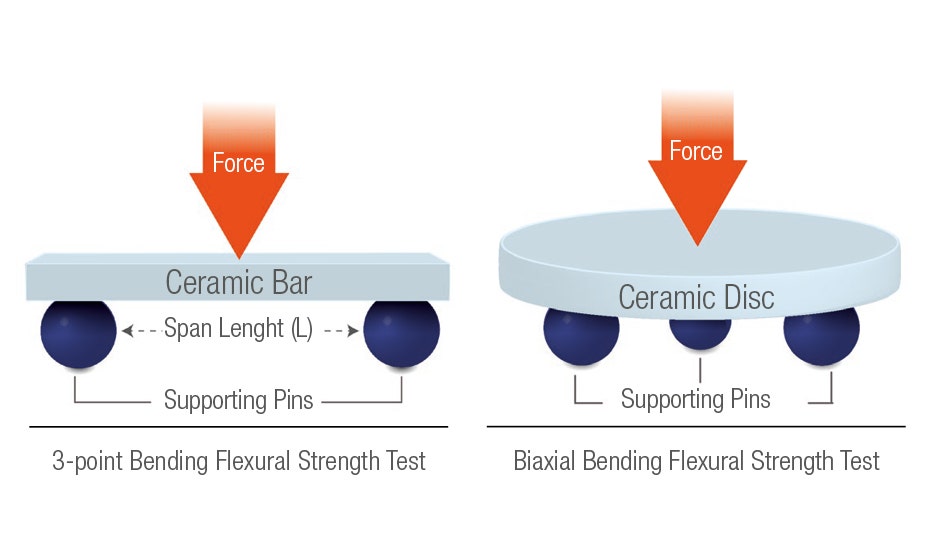

The most common method of measuring ceramic strength is by evaluating its flexural strength. The flexural strength test applies a force on the top of a ceramic specimen, which causes the specimen to bend and fracture. The International Standards Organization (ISO) and the American Dental Association have developed a standard for measuring the flexural strength of dental ceramics. Two methodologies are commonly used today. In the 3-point bend method (Figure 2), a rectangular specimen is used, whereas in the biaxial flexural strength method (Figure 3), a circular specimen is incorporated. Both tests are acceptable, however, ceramics tend to produce higher values when tested with the biaxial method over the 3-point bend method.

| Fig. 2. 3-point Bending Flexural Strength Test | Fig. 3. Biaxial Bending Flexural Strength Test |

Furthermore, even in a 3-point bending test, if the span length (see Figure 2) of the specimen is decreased, it can produce higher values of flexural strength of the same ceramic. It is critical to understand testing parameters when selecting or comparing different ceramic brands. All materials should be tested under the same conditions, and by using the same methodology.

3. Multi-chromatic vs multi-translucent

Kuraray Noritake was the first dental manufacturer to introduce multi-layered zirconia as a commercial product in 2013. Different concentrations of pigment-containing zirconia powder are utilized to make the zirconia discs and blocks multi-chromatic.

Multi-chromatic: KATANA™ Zirconia HTML PLUS/STML/UTML (Figure 4) were developed based on the concept of “lifelike appearance”, accurately and naturally mimicking the color and translucency of natural teeth. It has a top enamel layer, two transition layers, and a base body layer. The unique manufacturing technology from Kuraray Noritake allows each powder layer to seamlessly blend within a gradient profile that eliminates any demarcation lines between the different layers. The Yttria concentration remains similar in all layers; therefore, the strength of the zirconia does not deviate from layer to layer. The pigments (chroma) are adjusted in a way that produces different chroma among the layers, where the translucency stays the same.

Multi-translucent: KATANA™ Zirconia YML (Figure 5) is the latest KATANA™ multi-layered disc, with a well-balanced combination of color translucency and flexural strength gradation. It is also manufactured using multilayer technology, with different Yttria content in each layer.

Strength differs in each layer, providing enamel with 750 MPa, the transition-body with 1000 MPa, and the base layer with 1100 MPa flexural strength. These layers are perfectly harmonized with each other, since all fundamental production steps, including purification, refining of the zirconia raw material and the addition of essential components such as Yttria, are all processed in-house by Kuraray Noritake.

| Fig. 4. KATANA™ Zirconia HTML PLUS/STML/UTML | Fig. 5. KATANA™ Zirconia YML |

4. Cleaning zirconia

During trial-fitting, the zirconia restoration might become contaminated with salivary proteins, thereby reducing the bond strength. KATANA™ Cleaner (Figure 6) can be used to remove contamination. This can be easily achieved by rubbing KATANA™ Cleaner on the intaglio surface, and subsequently rinsing it with water. KATANA™ Cleaner has a high cleaning effect, due to the surface-active characteristic of MDP Salt.

5. Bonding to zirconia

There are several clinical situations where zirconia restorations benefit from resin bonding: restorations that are less strong or thin, lack retention, or rely on resin bonding, (ex. resin-bonded fixed partial prostheses, onlays, or laminate veneers). Prof. Markus Blatz, DMD, PhD, University of Pennsylvania School of Dental Medicine and his group introduced a three-step approach, known as the “APC Zirconia Bonding Technique”.

APC Step A: Air-particle abrasion, then application of P: Primer and finally Step C: Composite resin. MDP-based resin cemented restorations exhibit better margins long term. MDP has shown a very stable chemical bond to zirconia. Kuraray Noritake invented and introduced the Original MDP monomer in 1981. All Kuraray Noritake PANAVIA™ cement (Figure 7) brands contain this original MDP monomer.

| Fig. 7. Universal resin cement: PANAVIA™ SA Cement Universal | Fig. 6. KATANA™ Cleaner |

Kuraray Noritake is known for its legacy of inventing groundbreaking technologies in both resin and ceramic technologies. The company is committed to inventing the best quality materials that dental ceramists and dentists can use to treat their patients with confidence.