Blending strength and esthetics, this super-translucent, multilayered zirconia material offers fast and efficient chairside milling for exceptional restorations.

What’s in a name? More often than not, it depends on the name. And in the case of Kuraray Noritake Dental, it’s actually the merging of 2 names—Kuraray and Noritake—that makes all the difference. After joining forces over a decade ago, these companies brought together a history of researching and developing innovative products—from synthetic resins, nonwoven fabrics, and fine chemicals and chinaware. While today, Kuraray Noritake Dental is known for a much different product portfolio, this invaluable know-how in both organic and inorganic chemistries has led to a proven track record for delivering strong and esthetic restorative materials that are rooted in science to ensure reliable clinical success.

What’s in a name? More often than not, it depends on the name. And in the case of Kuraray Noritake Dental, it’s actually the merging of 2 names—Kuraray and Noritake—that makes all the difference. After joining forces over a decade ago, these companies brought together a history of researching and developing innovative products—from synthetic resins, nonwoven fabrics, and fine chemicals and chinaware. While today, Kuraray Noritake Dental is known for a much different product portfolio, this invaluable know-how in both organic and inorganic chemistries has led to a proven track record for delivering strong and esthetic restorative materials that are rooted in science to ensure reliable clinical success.

High-Quality Zirconia

“While most dental manufacturers purchase raw zirconia from a third party—usually a large industrial ceramic manufacturer—Kuraray Noritake Dental uses its own proprietary zirconia powder formulation, which allows the company to control the process from start to finish,” said Penelope Chang, DDS, a CEREC trainer and leader in CAD/CAM dentistry who maintains a practice in Tenafly, NJ.

Fast & Efficient Chairside Milling

Fast & Efficient Chairside Milling

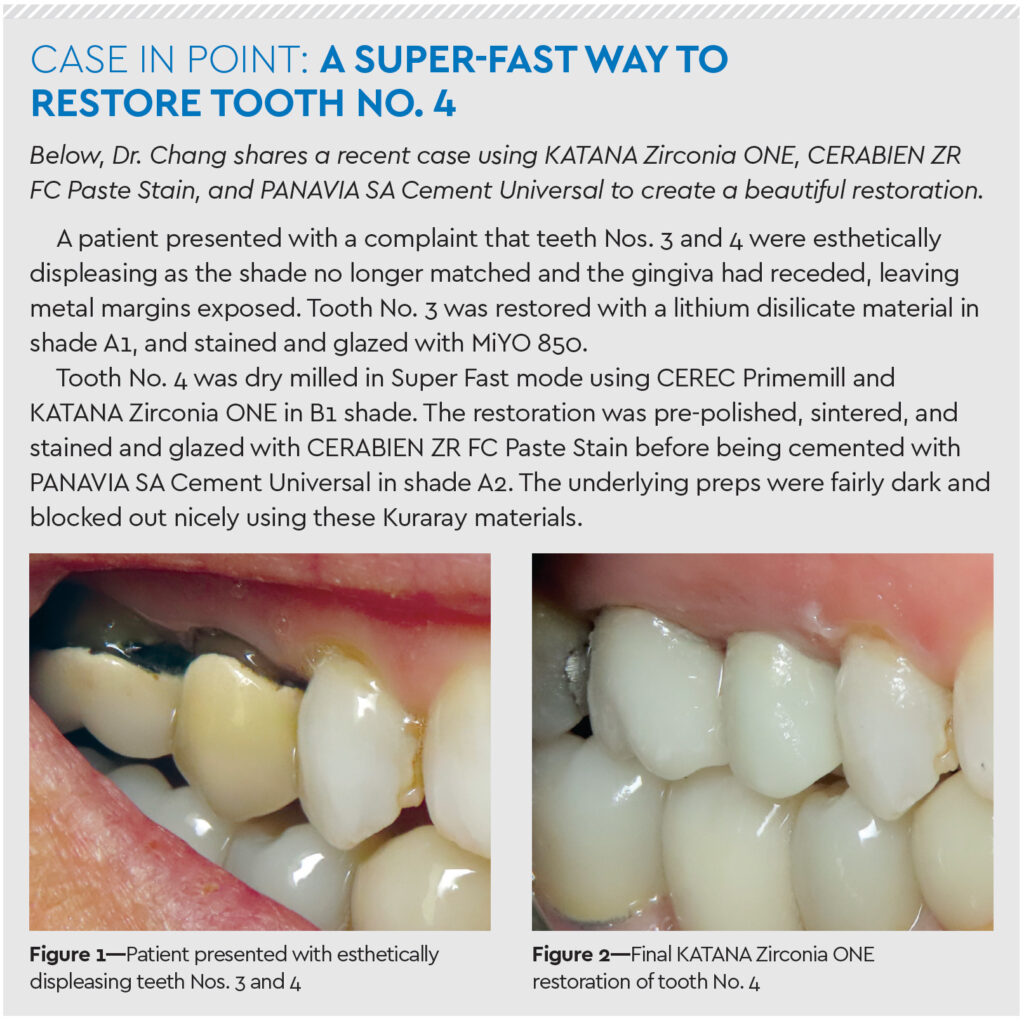

Now, a unique collaboration blends this superior materials technology with Dentsply Sirona’s CEREC Primemill milling unit and CEREC SpeedFire sintering oven—making it possible to mill in under 5 minutes and sinter a full zirconia restoration in just 18 minutes. But this possibility is only a reality thanks to KATANA Zirconia ONE, a super-translucent, multilayered material designed for fast and efficient chairside milling.

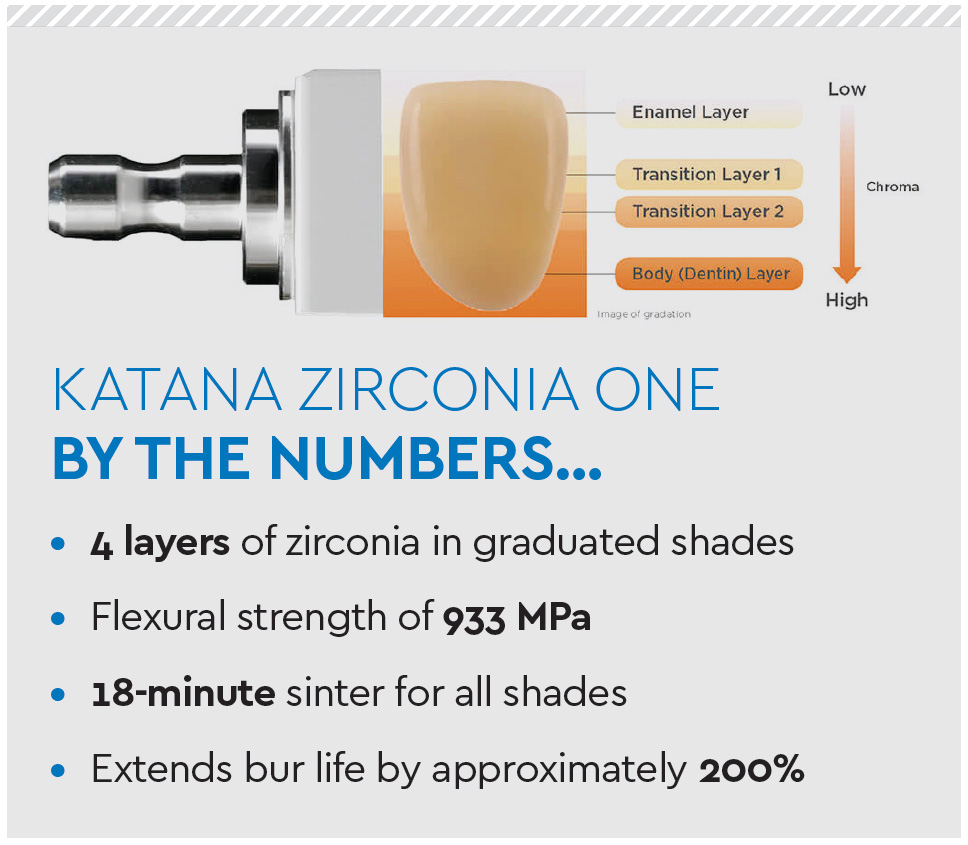

“The KATANA Zirconia ONE block has 4 layers— enamel, 2 transitional, and dentin—and the manufacturing technology allows each powder layer to seamlessly blend within a gradient profile, eliminating any demarcation lines between the different layers,” said Dr. Chang. “Additionally, the Yttrium concentration remains similar in all the layers so that the strength of the zirconia does not deviate from layer to layer. This allows for beautiful chroma and translucency with exceptional strength.”

One Block, 4 Layers

With a flexural strength of 933 MPa, KATANA Zirconia ONE offers improved strength and esthetics, as well as smooth margins for an exceptional fit. Available in 2 sizes—Crown and Bridge Block—it also streamlines inventory management.

As far as esthetics go, the block’s multilayer composition allows for a seamless blend with natural transition and no need for additional sintering time. The restoration can be easily positioned within the layers by using the CEREC Move Tool.

“The block size allows flexibility to position the restoration to have more translucency or chroma,” said Dr. Chang. “The restorations blend nicely, especially when a glaze is applied after polishing.”

More than ONE Place to Go

Dr. Chang particularly enjoys using KATANA Zirconia ONE in the posterior where extra strength is needed, such as when restoring a patient who bruxes or on an implant-supported abutment. It’s also a great choice in cases that require minimal tooth reduction, such as a short clinical crown.

“KATANA Zirconia ONE is unique from other restorative materials because it takes less than 5 minutes to dry mill

in Super Fast mode with CEREC Primemill.”

“Honestly, it can be used anywhere in the mouth—it’s that pretty,” she added. “Katana ONE has a minimum material thickness of only 0.8 mm, which is 0.2 mm less than almost all other blocks. This actually makes a huge difference if, for example, you have slightly under-reduced the occlusal.”

After milling is complete, technicians and doctors can choose their preferred finishing technique: pre-sinter polish, post-sinter polish, or glaze with Kuraray’s CERABIEN ZR FC Paste Stain, which allows them to further characterize the sintered zirconia.

“KATANA Zirconia ONE is unique from other materials because it takes less than 5 minutes to dry mill in the Super Fast mode with CEREC Primemill. Combine that with an 18-minute sintering time and you can fabricate a full zirconia single-unit restoration in about 35 minutes!” exclaimed Dr. Chang.

A Winning Workflow

As an early adopter of CEREC technology and a practice owner for 20 years, Dr. Chang has seen firsthand how evolutions in both milling machines and restorative materials—including this innovative multilayered zirconia block— have made a world of difference for her patients as well as her practice.

“It is great being able to offer esthetic zirconia restorations chairside that have such a fast workflow,” Dr. Chang concluded. “Patients can be restored in a shorter appointment time, while I have a wider range of choices available to provide the best possible restoration for the patient.”